In the electronic industry, the manufacture of printed circuit-board assemblies (PCBAs) has been greatly simplified by the adoption of “no-clean” fluxes during the soldering process. This “no-clean” solder paste intends to eliminate the need for cleaning the circuit boards after assembling all the metal parts into them. This type of flux is marketed to, and assumed to not leave significant amounts of active residue on the board’s surface after soldering, but multiple studies suggest that this is not necessarily the case.

No-clean” fluxes can save expensive steps in electronic card manufacturing, they are safe, effective, and reliable when used properly. However, it has been demonstrated that even “no-clean” solder paste can lead to electrochemical migration and dendritic growth, which are one of the most common causes of failures in PCBAs. With this in mind, this article aims to showcase the importance of cleaning even “no-clean” fluxes in printed circuit board assemblies.

Why Clean Electronic Assemblies?

Cleaning PCBAs before applying the conformal coating is a critical step that influences the reliability and performance of electronic devices. Conformal coatings are thin polymeric films applied to PCBAs to safeguard them against environmental factors such as moisture, dust, chemicals, and corrosion [1]. It enhances the circuit board's longevity and prevents product returns for manufacturers. However, failure to adequately clean the PCBAs before coating can lead to a range of problems that undermine these protective benefits.

Contaminants such as flux residues, dust, and other particulates left behind during the assembly process can impair the adhesion of conformal coatings to the PCB surface. This compromised adhesion can result in coating delamination, reduced effectiveness in protecting against moisture, and increased vulnerability to corrosion. Even in cases where “no-clean” solder pastes are used, the residues they leave behind can interfere with coating adhesion, and negatively impact the board’s performance [2].

Moreover, one of the most concerning consequences of insufficient cleaning is the formation of dendrites, which are microscopic conductive filaments that can bridge closely spaced conductive traces on the PCB. This might lead to short circuits, electrical failures, and compromised functionality, posing significant risks to the device's operation and potentially resulting in costly recalls or repairs. It is estimated that failures due to electrochemical migration have increased in recent years compared to what the industry experienced in the 70’s through 90’s [3].

How Do Dendrites Grow on Electronic Assemblies?

Flux residues on the circuit’s board surface can lead to a process called Electrochemical Migration. It is the formation of conductive metal filaments across a printed circuit board (PCB) when dense current leakages occur, in the presence of an electrolytic solution. The outcome of this process is the formation of dendrites, which cause surface contamination, device sensitivity, and a rise in flux residues. These dendrites are a common root cause of field failures, and they can be either intermediate or permanent.

PCBA's reliability is highly affected by the chemistry of the soldering materials, and the activity and ionic nature of the residues. Other key factors that can contribute to electrochemical migration are the PCB material composition (plating chemistry), uncleaned flux residue, active chemistry concentration and distribution, board surface roughness, and the environmental conditions to which the PCB gets exposed (e.g., Humidity, Temperature).

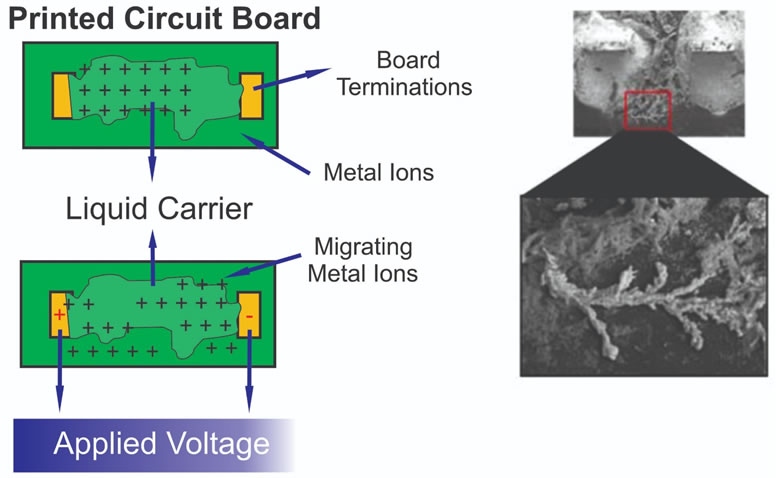

Figure 1: Dendrite Growth due to electrochemical migration in PCBAs [4]

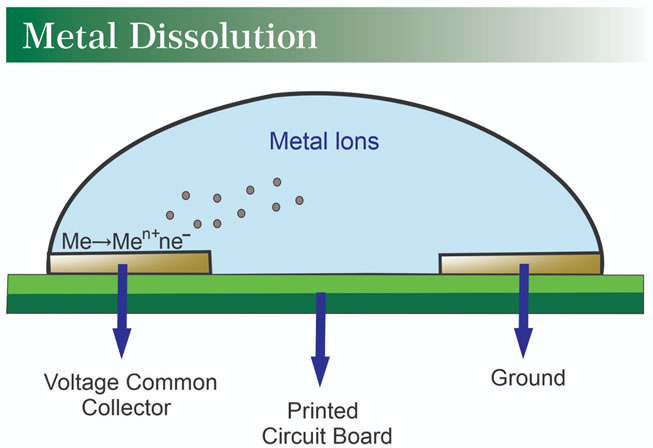

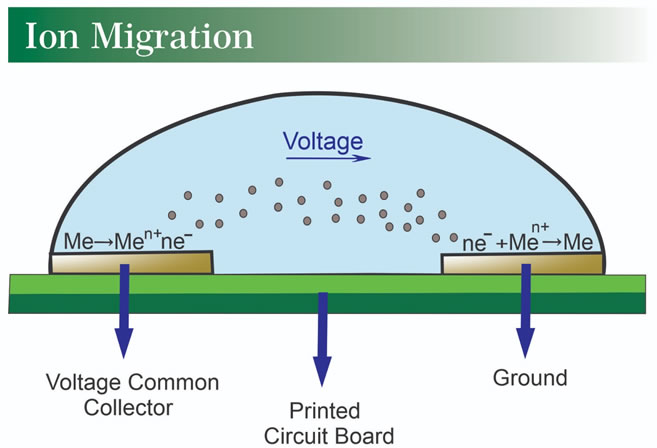

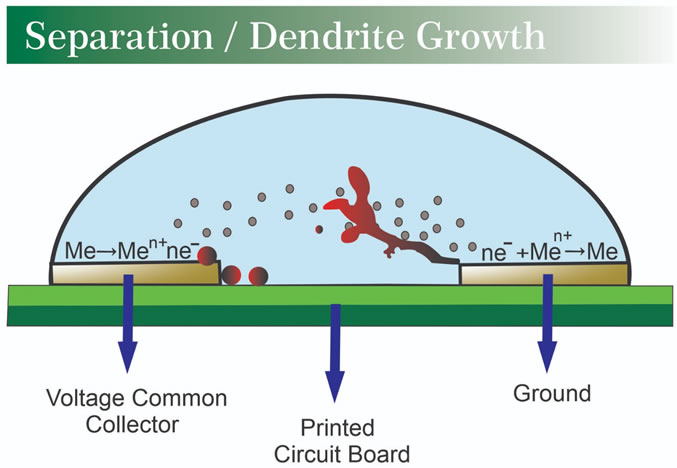

An overview of the electrochemical migration process inside a PCBA is presented in Figure 1. The chemical reaction within a PCBA involves the copper in the board as well as the inorganic and organic compounds that constitute the substrate. Other substances, such as the flux, can also participate in the electrochemical migration process, which is divided into three (3) steps:

1. Metal dissolution: A strong alkaline condition attacks the anode and the power-leading contacts respectively – usually created by environmental pollutants or flux residue. The reaction spreads from the deplating anode to the cathode, forming dried corrosive residue along the printed circuit board.

2. Ion Migration: It is determined by the concentration of the ions, in which they spread out to the areas where there is an alkaline condition. This step is the precursor for the dendrites to grow along the concentration gradient. The current flow promotes the upcoming dendrite formation, and potential short on PCBAs.

3. Dendrite Growth: Near the cathode (ground potential), there is normally a high acidic condition and a positively charged ion concentration. The reduction in negatively charged ions leads to the deposition of positively charged ions as metal dendrites. Dendrite growth is just a micro plating cell that drives the metal to build a bridge between the cathode and the anode.

The whole process finally results in highly conductive bridges or filaments, that build up along glass fibers in the PCB substrate material. The composition of these formations can vary from pure metal (slow growth) to metal-metal oxide composites (moderate growth) [5].

Importance of Flux

Whenever you are soldering electronic pieces into a board, the solder needs to make a good bond to the parts that you are soldering onto. The metal of the parts and the metal of the solder need to come into direct contact with each other, to create a reliable connection. However, since metals naturally form an oxide layer because of the oxygen in the air, something is needed to remove that oxide layer. Here is where flux, or soldering paste, comes into play because it removes that oxide layer.

Usually, the solder that manufacturers use for electronics will already have flux within it, but it is also helpful to have flux available to use separately. The oxide layer needs to be removed since it creates a barrier that prevents the solder and the metal (copper, silver, gold, etc.) from bonding together. In that sense, when the flux heats up and gets near the temperature of melted solder, it becomes corrosive and gets rid of the oxide layer both in the metal and the solder itself [6].

During the soldering process, the solder comes into contact with the flux at high temperatures and both of them start melting away. The solder flows and smoothly bonds to the metal, which makes it look shiny and wet. On the other hand, the solder paste sizzles, it starts to melt away from the board, leaving some residue behind that would need to be cleaned off. In the industry, solder flux selection is critical to the performance of any PCBA, since flux helps form a stronger joint.

What Are The Types of Fluxes?

There are three (3) main types of solder fluxes available in the market [7]:

Water Soluble FluxAdvantages

- Has remained the industry standard for decades, and the demand is expected to grow by 5% in the upcoming five years.

- Highly active which provides good soldering performance, it barely burns off during soldering and properly cleans the metal for proper welding.

- There are 3 varieties: halide-activated (pH neutral), halide-activated (low pH), and halide-free.

- The chemistry could be corrosive and could aggressively react with the metal even after soldering.

- Since it can continue reacting after soldering, it is a long-lasting flux on circuit assemblies.

- Machine cleaning is necessary to ensure neat circuit assemblies, which makes the whole process longer and more expensive.

Rosin-Based Flux

Advantages

- Can deliver top-notch soldering, cleans the metals you want to solder, and remain there until the procedure is complete.

- Similar performance to the water-soluble flux but without the drawbacks. Therefore, the surface won't be harmed or corroded by it.

- Any remaining flux behaves as a barrier once the soldering process is over, trapping ionic residues and preventing them from reacting.

Challenges

- Rosin flux has the major drawback of leaving a residue on the PCB assembly.

- Could contaminate the machinery used in manufacturing. The flux also appears to function ineffectively in harsh conditions.

- The cleaning process can be rather expensive. However, you can ignore this drawback if you use a solvent in the workflow.

No-Clean Flux

Advantages

- No-clean flux leaves a negligible amount of residue, meaning that it leaves little to no active compound on the PCB after soldering.

- Eliminates the need for longer machine cleaning processes, which also reduces the overall cost of card manufacturing.

- Has low solids content, and can be alcohol-based for speedy evaporation and flux spattering reduction.

Challenges

- Given the low solids and active chemistry, it could be challenging to get an effective soldering performance.

- Although adding active chemistry enhances performance, it also increases the amount of residue left on the PCBA.

- PCBAs are less tolerant to residue than in the past, increasing the chance of failure owing to residue.

Why Clean “No-Clean” Fluxes?

Multiple manufacturers have reported that circuit boards soldered in the presence of “no-clean” flux had to be cleaned as a result of problems that came up during in-circuit testing. Test pins did not always fully penetrate to make adequate electrical contact with respective test pads, which left sticky residues after reflowing. Additionally, pins needed routine repair owing to residue buildup that reduced their precision. Modern generations of “no-clean” solder pastes, however, seem to be almost free of these issues.

The issue with these residues is that they might already be conductive when they are applied to the PCB, or that they might gradually start to conduct over time. The remaining flux residue most likely won't matter on low-voltage, low-density boards. On high-density voltage circuit boards though, solder balls may become stuck in no-clean flux residue between components. To mediate this risk, it’s advisable to outline a cleaning process to eliminate residues.

In the industry, “No-clean” fluxes are normally cleaned off by assemblers in the following situations [8]:

- To prevent circuit malfunction in circuits with clock rates greater than 1 GHz.

- To improve adhesion of the conformal coating and underfilling materials.

- To ensure more accurate inspection and quality control.

- To improve appearance by eliminating tiny objects like solder balls.

Soldering using “no-clean” paste does not always work well as PCBs become more complex and are being packed in tighter spaces by designers. Manufacturers are using flip-chips, micro-BGAs, quad-flat no-leads (QFN) packages, and chip-scale packaging (CSP) components in smaller locations on boards as the need for microscopic electronics rises. If the boards are not properly clean, the miniaturization, high density, and complexity tend to produce problems.

Flux residue on PCBs may cause issues like shorting, parasitic leakage, dendritic growth, and electrochemical migration. Cleaning the no-clean flux residue is therefore no longer a choice; it is now required for long-term PCBA’s performance, functionality, and dependability [9].

Should I Clean My PCBA Before coating?

In response to the boosted intricacy of contemporary PCBs, manufacturers are increasingly inclined to clean all PCBs, not only those managing high-density energy. This helps avoid erratic field performance, costly board failures, and potential product recalls or returns. The primary rationale behind removing “no-clean” flux and its residual traces from the PCB surface is to prevent signal transmission interference and electronic circuit malfunction.

This holds true not only for high-frequency circuits but also for high-voltage and high-impedance systems. Tightly packed component arrangements in electronic boards often lead to solder ball formation, which is made worse by additional contaminants like ink and fingerprints. Consequently, during cleaning, assemblers address both “no-clean” solder paste residues and other pollutants, fostering optimal board functionality.

Beyond functional advantages, board surface cleaning offers cosmetic improvements, facilitating enhanced inspection and quality control in the electronic industry. Moreover, a clean surface promotes a better adherence to conformal coatings at the end of the printed circuit board assemblies. For applications that require high reliability − such as in the military, medical, robotics, and aerospace domains − cleanliness emerges as a key element [10].

Selecting The Best No-Clean Flux Remover

There are many “no-clean” flux removers on the market, and they range in strength. These cleaning agents are offered in spray cans or bulk so that automated equipment can hold them. Generally speaking, the cleaner and the solvent should be potent enough to remove any flux residue but not so potent as to harm the components, exposed wires, the solder mask, the silkscreen, or the cleaner. At Techspray, we can offer advice on how to use our products for the specific flux you are using.

Based on the chemistry of the flux, the type of residue (hard or soft), and the number of solids in the flux, we can help you select the best cleaning method to use. For example, fluxes containing halides typically produce more residue, but they can be easily removed by employing gentle cleaning chemicals and quick wash cycles. Halide-free no-clean fluxes, on the other hand, do not leave behind as much debris but could be more challenging to clean.

Take a look at our line of flux-removing products:

That concludes our Insight on the Importance of cleaning PCBAs before conformal coating. Still have questions about which flux-removing products are best for your applications? Contact us at 678-819-1408, or send us a message here.

References

[1] Rathinavelu, U., Jellesen, M. S., Moller, P., & Ambat, R. (2012). Effect of no-clean flux residues on the performance of acrylic conformal coating in aggressive environments. IEEE Transactions on Components, Packaging and Manufacturing Technology, 2(4), 719–728. https://doi.org/10.1109/tcpmt.2012.2186456

[2] Seelig, K., & O’Neill, T. (2013, January). Conformal Coating over No Clean Flux. https://www.ipc.org/system/files/technical_resource/E2%26S12_01.pdf

[3] Isaacs, P., & Munson, T. (2016, January). What makes no-clean flux residue benign? IEEE Xplore. https://ieeexplore.ieee.org/document/7428404

[4] Kester. Why Clean a No-Clean Flux, 2016, www.kester.com/Portals/0/Documents/Knowledge%20Base/Publications/International%20Conference%20on%20Soldering%20and%20Reliability%20ICSR%202016_paper_Why%20Clean%20A%20No-Clean%20Flux.pdf?ver=2017-01-26-102146-280.

[5] Munson, T. (2012). What is Electrochemical Migration – Dendrite Shorting of Electronic Circuits? Foresite Inc. https://dokumen.tips/documents/foresite-inc-a-what-is-electrochemical-migration-a-dendrite-shorting-of-.html?page=1

[6] Beavers, I. (2022, August). A practical guide to solder flux. MacroFab, Inc. https://www.macrofab.com/blog/practical-guide-solder-flux/

[7] Groves, E. (2016, November). Choosing the Correct Flux: Types and Their Advantages/Disadvantages. Pillarhouse International. https://www.pillarhouse.co.uk/wp-content/uploads/301-Choosing-a-Flux-11-2016.pdf

[8] Akber, R. (n.d.). Is it necessary to clean no-clean flux? Electronic Design. https://www.electronicdesign.com/markets/automation/article/21147793/rush-pcb-is-it-necessary-to-clean-noclean-flux

[9] Cadence System Analysis. “Inner and Outer Layer Electrochemical Migration in a PCB.” Inner and Outer Layer Electrochemical Migration in a PCB, 28 Feb. 2023, https://resources.system-analysis.cadence.com/blog/inner-and-outer-layer-electrochemical-migration-in-a-pcb

[10] Richardson, M. (2021, June 11). Cleanliness Before Coating. Aerospace Manufacturing. https://www.aero-mag.com/cleanliness-before-coating