With the increased popularity of miniaturized electronics and circuitry, conformal coating use has skyrocketed to solidify its relevance in a wealth of modern PCB-related applications . Choosing the ideal type of coating and application methods for your electronics is crucial. However, processing the vast amount of information online can often present a daunting task.

Well, not anymore!

In this article, you’ll be given all the information that you need to identify the ideal conformal coating for your application’s requirements. If you are searching for something specific, feel free to use the index for a more selective approach. Otherwise, this article is helpful both for beginners who seek to understand conformal coating methodology and use, and for seasoned applicators and businesses who wish to confirm their knowledge-base and procedural legitimacy. You can also check out our selection of conformal coatings here.

Types of Conformal Coating

Application Methods

Thickness Measurement

Curing Methods

Removal Methods

Certifications

Regulatory Considerations

What is Conformal Coating

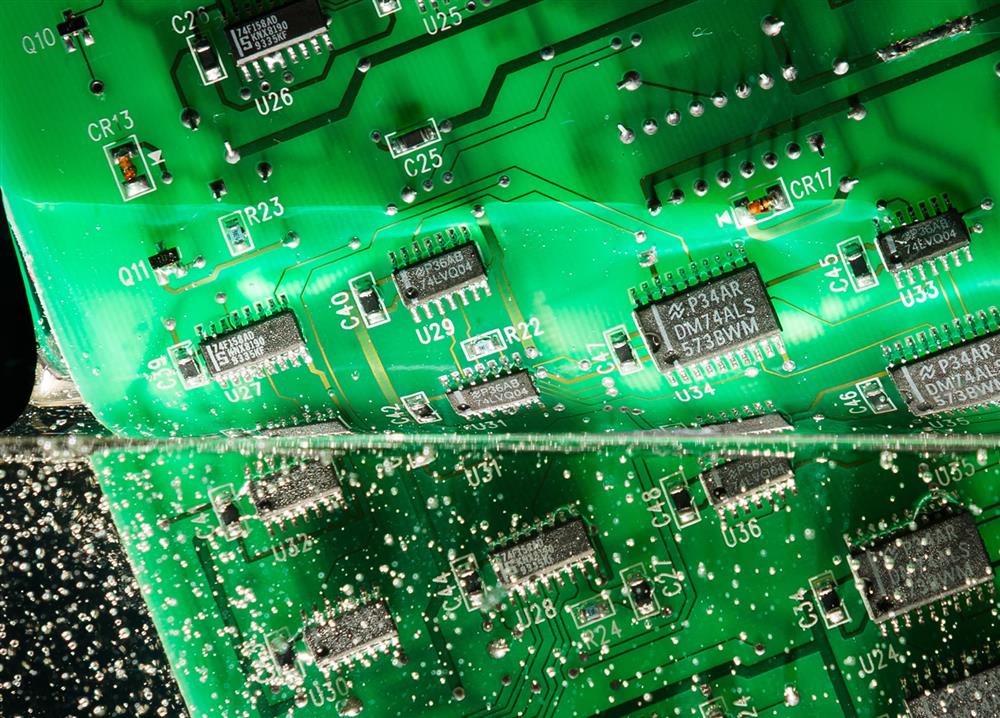

Conformal coating is a special polymeric film forming product that protects circuit boards, components, and other electronic devices from adverse environmental conditions. These coatings ‘conform’ to inherent irregularities in both the structure and environment of the PCB. They provide increased dielectric resistance, operational integrity, and protection from corrosive atmospheres, humidity, heat, fungus, and airborne contamination such as dirt and dust.

What are the Types of Conformal Coating

There are several options for coating technologies, and the best option for your particular application should depend primarily on your level of necessary protection. The application method and the ease of rework are also important factors, but should generally be considered secondary to the necessary protective performance.

Traditional Conformal Coatings

What we call “traditional” conformal coatings are 1-part systems that have a resin base and can be diluted with either solvent or (in rare cases) water. Traditional coatings are semi-permeable, which is why they are not fully hermetic nor do they seal the coated electronics. They provide resistance to environmental exposure, which increases PCB durability while keeping application and repair processes in practice. However, they are NOT fully water-proof.

The following categories are based on the basic resin of each coating. The chemical composition of each conformal coating determines its major attributes and functions. Choosing the proper conformal coating for your application is determined by the operational requirements of your electronics.

- Acrylic Resin (AR) – Acrylic conformal coating provides fair elasticity and general protection. Acrylic conformal coating is recognized for its high dielectric strength, and fair moisture and abrasion resistance. What generally distinguishes acrylic coating from other resins is its facility for removal. Acrylic coatings are easily and quickly removed by a variety of solvents, often without requiring agitation. This makes rework and even field repair very practical and economical. On the other hand, acrylic coatings do not protect against solvents and solvent vapors, which could result in less than ideal performance for an application that involves something like pumping equipment. Acrylic coatings can be considered basic, entry-level protection, because they are economical and protect against a broad-level of contamination. However, they are not the best-in-class for any characteristic except possibly dielectric strength.

- Silicone Resin (SR) – Silicone conformal coating provides excellent protection in a very wide temperature range. SR provides good chemical resistance, moisture, and salt spray resistance, and is very flexible. Silicone conformal coating isn’t abrasion resistant because of its rubbery nature, but this property does make it resilient against vibrational stresses. Silicone coatings are commonly used in high-humidity environments. Special formulations that can coat LED lights without color shift or reduction of intensity are available, and make SR conformal coatings a popular choice for applications such as outdoor signs. Removal can be challenging, requiring specialized solvents, long soak time, and agitation from a brush or an ultrasonic bath.

- Urethane (Polyurethane) Resin (UR) – Urethane conformal coating is known for its excellent moisture and chemical resistance. It is also very abrasion resistant. Combining those factors with its solvent resistance results in a conformal coating that is very difficult to remove. Like silicone, full removal generally requires special solvents, long soak time, and agitation with a brush or an ultrasonic bath. Urethane conformal coating is commonly specified for aerospace applications where exposure to fuel vapors is a common concern.

The rest of this article is concerned mainly with what we call “traditional” conformal coatings, but we’ll first cover other coating types to provide a complete picture of the options available.

- Epoxy Conformal Coating - Epoxy resins (ER) are usually available as two‐part compounds and create a very hard coating. Epoxy conformal coatings provide very good humidity resistance and are not generally permeable, unlike traditional conformal coatings. They also have high abrasion and chemical resistance. Typically, they are very difficult to remove once cured and are not as flexible as the other materials. Epoxy coatings are common in potting compounds, which in contrast to conformal coatings, completely cover the electronics in a solid and level layer of material.

- Parylene Conformal Coating - Parylene conformal coatings are a unique type of coating applied by vapor phase deposition. They provide excellent dielectric strength and superior resistance to moisture, solvents, and extreme temperatures. Because of the vapor deposition method, parylene coatings can be applied thinly and still provide excellent circuit board protection. However, removal for rework is very difficult, requiring abrasion techniques, and without access to vapor phase deposition equipment, recoating with parylene is impossible.

- Thin Film /“Nano” Coatings - A coating is dissolved in a fluorocarbon‐based carrier solvent and applied with a spray or dip method to create a very thin coat, although not at a nanometer scale as the nickname suggests. They are commonly used to provide a minimal amount of hydrophobicity, which may prevent losses from very quick exposure to water. This type of coating does not offer the level of surface protection that other coating methods do.

How To Apply Conformal Coating

Once the type of coating is selected, the next question is how to apply the conformal coating. This decision should be based on the following variables:

- Production throughput requirements – The necessary prep work, the speed of the coating process, and how quickly the boards can be handled after the coating process.

- Board design requirements – Connector-laden designs, solvent-sensitive components, and other issues impact your decision.

- Equipment requirements – If a coating is only sporadically required, tying up capital and floor space with additional equipment may not make sense.

- Pre-coating processing – Some processes require masking or taping before coating in order to prevent coating of unwanted surfaces.

- Quality requirements – Mission critical electronics that require a high degree of repeatability and reliability will generally require more automated application methods.

The following are the application methods for traditional conformal coatings:

- Manual spraying - Conformal coating can be applied with an aerosol can or handheld spray gun. It is generally used for low volume production when capital equipment is not available. This method can be time-consuming because areas not requiring coating need to be masked. Also, quality and consistency of outcome are operator-dependent, so variations are common from board to board.

- Automated spraying – A programmed spray system that moves the board on a conveyor under an alternative spray head that applies a conformal coating.

- Selective coating - An automated conformal coating process that uses programmable robotic spray nozzles to apply the conformal coating to very specific areas on the circuit board. This process is used in high volume processes and can eliminate the need for masking. An applicator may have a built-in UV lamp to cure coating immediately after it is applied.

Photo courtesy of PVA

- Dipping - The circuit board is first immersed, then withdrawn from the conformal coating solution. Immersion speed, withdrawal speed, immersion time, and viscosity determine the resulting film formation. It is a common conformal coating technique for high volume processing. A great deal of masking is generally required before the coating process. Dipping is only practical when coating on both sides of the board is acceptable.

- Brushing - Brushing is a simple application technique used mainly in repair and rework applications. The conformal coating is applied with a brush to specific areas on the board. It is a low-cost method but it requires a lot of manual labor and is highly variable depending on operator proficiency and consistency This method is best suited for small production runs.

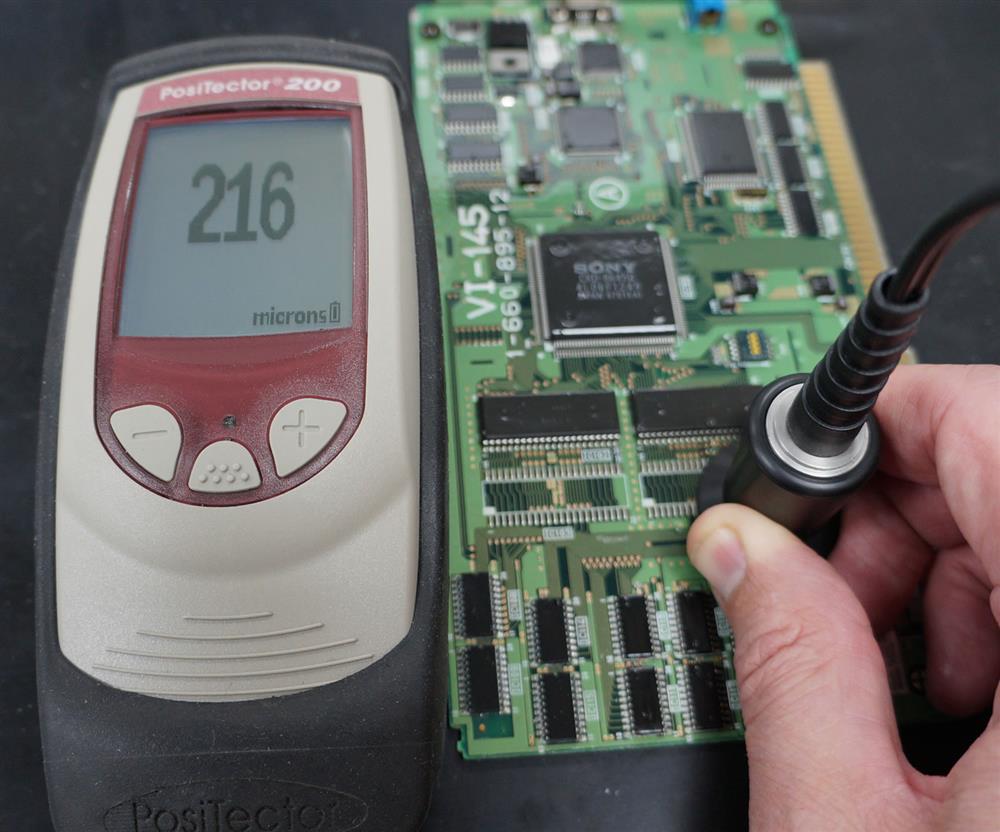

How To Measure Conformal Coating Thickness

Conformal coatings are usually applied as very thin coatings, providing the maximum amount of protection possible while still using the thinnest amount of material. The thinness of the coatings minimize heat entrapment, unnecessary additional weight, and a variety of other concerns. Common thickness with most conformal coatings is anywhere between 1 to 5 mils (25 to 127 microns) with some coatings applied at an even thinner level. Anything greater than this thickness is usually an encapsulate or a potting compound, which typically provides more mass and thickness to protect the boards.

There are three primary ways to measure the thickness of a conformal coating.

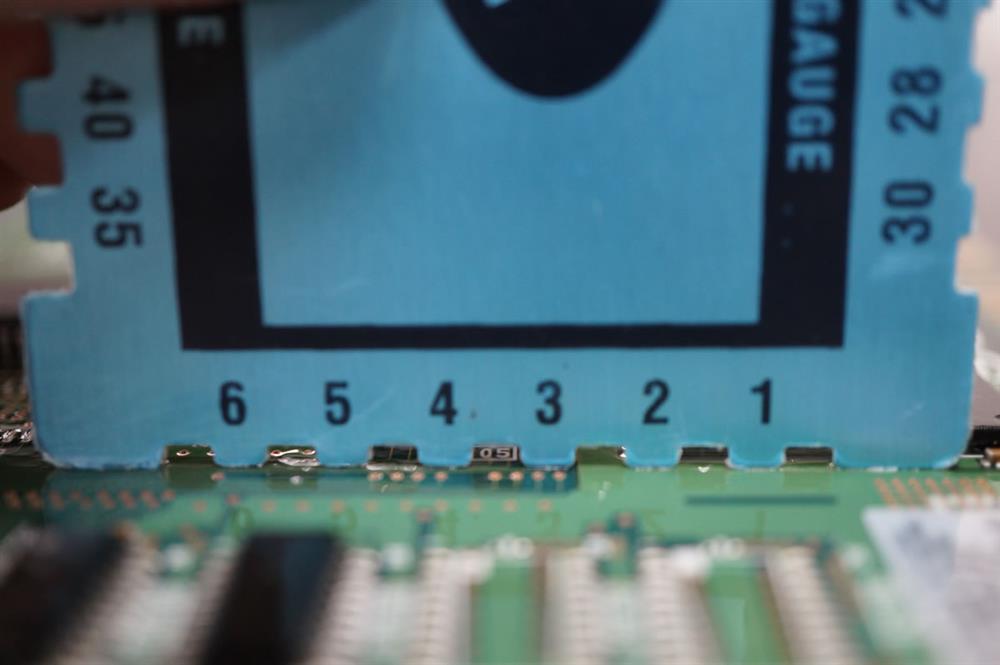

- Wet film thickness gauge - Wet film thickness can be measured directly by using the appropriate gauge. These gauges incorporate a series of notches and teeth, each tooth having a known and calibrated length. The gauge is placed directly onto the wet film for the film measurement. See http://www.geionline.com/wet-film-gauge. This measurement is then multiplied by the percent of solids in the coating to calculate the approximate dry coating thickness.

- Micrometer - Micrometer thickness measurements are taken on the board (or on a test panel) at several locations before and after coating takes place. The cured coating thickness is subtracted from the uncoated measurements and divided by 2, providing the thickness on one side of the board. The standard deviation of the measurements is then calculated to determine the uniformity of the coating. Micrometer measurements are best taken on harder coatings that do not deform under pressure.

- Eddy current probes – The Eddy current measurement of conformal coating thickness uses a test probe that directly measures the thickness of a coating by creating an oscillating electromagnetic field. The thickness measurements are both non-destructive and very accurate, but can be limited depending on the availability of a metal backplane or metal under the coating, and the direct contact available of the test sample. Without metal below the test area, no measurements will be made, and if the probe does not fit flat on the test area, readings will be inaccurate.

- Ultrasonic thickness gauge – This type of gauge measures coating thickness using ultrasonic waves. It has an edge over the eddy current probes because it does not need a metal backplane. Thickness is determined by the amount of time the sound takes to travel from the transducer, through the coating, onto the surface of the board, and then back through the coating to the transducer. A conductive medium, like propylene glycol or water, is needed to provide good contact with the surface. This is generally considered a non-destructive test unless there is a concern with the conductive medium affecting the coating.

Curing Methods

While the curing mechanism is not a primary criterion when selecting a coating, it has a direct impact on the type of application method that will be feasible, and the throughput that can be expected. Some mechanisms are relatively infallible, while others are very complex and leave room for application errors when used in an uncontrolled process.

- Evaporative Curing Mechanism - The liquid carrier evaporates, leaving just the coating resin. Although very simple in theory, circuit boards usually need to be dipped at least two times to build up an adequate coating on the edges of their components. Whether the liquid carrier is solvent or water‐based, humidity affects application parameters. Solvent systems tend to be easy to process, and provide consistent coverage due to good wetting, and fast cure times. However, solvents are often flammable, so adequate ventilation and fume extraction methods are required. Using water as a carrier can eliminate the flammability concern, although these coatings tend to take much longer to cure, and can be very sensitive to ambient humidity.

- Moisture Curing - Primarily found in silicone and some urethane systems. These materials will react with ambient moisture to form the polymer coating. This type of curing mechanism is often coupled with an evaporative curing. As carrier solvents evaporate, moisture reacts with resin to initiate final curing.

- Heat Curing - Heat curing mechanisms can be used with one or multicomponent systems, as a secondary curing mechanism for UV curing, moisture curing, or evaporative curing. The addition of heat will cause the system to polymerize or speed the curing of the system. This can be advantageous when one curing mechanism is insufficient to gain the curing properties required or expected. However, thermal sensitivity of circuit boards and components must be taken into consideration when curing at high temperatures.

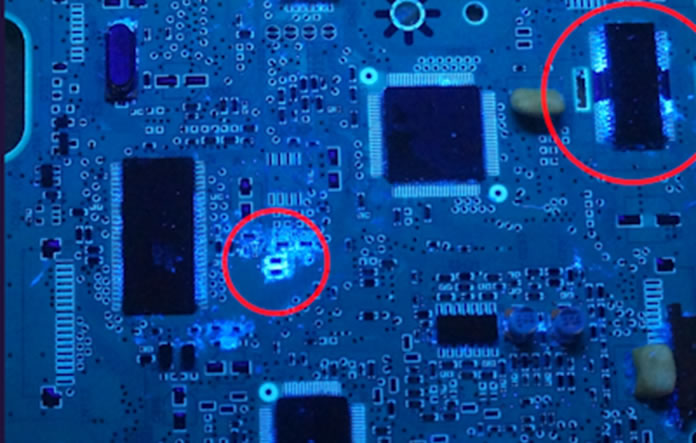

- UV Curing - Coatings that are cured using ultraviolet light offer very fast throughputs. They are 100% solid systems with no carrier solvents. UV curing occurs in the production line, so a secondary curing mechanism is needed under the components and in shadowy areas. UV cured coatings are more difficult to repair and rework and require UV curing equipment and UV radiation protection for workers.

How to Removal Conformal Coating

On occasion, it is necessary to remove a conformal coating from the circuit board to replace damaged components or perform other reworking procedures. The methods and materials used to remove coatings are determined by both the coating resins and the size of the area, which can impact the time required for removal.

The basic methods as cited by IPC are:

- Solvent Removal – Most conformal coatings are susceptible to solvent removal; however, it must be determined if the solvent will damage parts or components on the circuit board. Acrylics are the most sensitive to solvents hence their easy removal. On the other hand, epoxies, urethanes, and silicones are the least sensitive. Parylene cannot be removed with a solvent.

- Peeling – Some conformal coatings can be peeled from the circuit board. This is mainly a characteristic of some silicone conformal coatings and some flexible conformal coatings.

- Thermal/Burn‐through – A common technique of coating removal is to simply burn through the coating with a soldering iron as the board is reworked. This method works well with most forms of conformal coatings.

- Microblasting – Micro blasting removes the conformal coating by using a concentrated mix of soft abrasive and compressed air to abrade the coating. The process can be used to remove small areas of the conformal coating. It is most commonly used when removing Parylene and epoxy coatings.

- Grinding/Scraping – In this method, the conformal coating is removed by abrading the circuit board. This method is more effective with harder conformal coatings, such as parylene, epoxy and polyurethane. This method is only used as a method of last resort, as serious damage can be incurred.

If all you are doing is replacing a component or working on an isolated area, it is common to simply burn through the coating with a soldering iron. In cases when this is aesthetically unacceptable, contamination is a concern, or components are densely spaced, coating removers are available in pen packaging.

Certifications

Certifications are an important way to distinguish general purpose varnishes and shellacs from engineered coatings designed specifically for PCB protection. Although there are dozens of user and industry specifications, the two major certifications are IPC-CC-830B and UL746E. When selecting a coating, look for the availability of 3rd party test documentation, rather than coatings with the claim that “they meet the requirements”. Both standards use the UL94 standard to judge flammability, with a V-0 rating signifying the lowest flammability potential.

IPC-CC-830B / MIL-I-46058C

This standard originated with the military standard MIL-I-46058C, which became obsolete in 1998. The civilian version IPC-CC-830B is nearly identical, so it is generally understood that if a board passes the IPC spec it will also pass the MIL spec., and vice versa. IPC-CC-830B is a battery of tests, some are pass-fail and others provide data that can be referenced and compared to:

- Appearance

- Insulation resistance

- UV fluorescence

- Fungus resistance

- Flexibility

- Flammability

- Moisture and insulation resistance

- Thermal shock

- Hydrolytic stability

UL746E

Underwriters Laboratories (UL) is considered a credible and reliable safety certification body worldwide, and UL certification is commonly required for consumer goods. UL746E tests for the electrical safety and flammable safety of coated electronics. For electrical safety, there is a battery of tests similar to IPC-CC-830B, but with a cycling current load to constantly measure the failure of the isolative properties of the coating. The flammability test uses the UL94 standard like IPC-CC-830B, which involves attempting to light the cured coating with an open flame and observing the sustainability of the flame.

Once a coating has passed the UL746E standard, it can be registered with UL and assigned a registration number. Products certified and registered to UL746E standards can include the UL symbol (which looks like a backward “UR”). To maintain the registration, a coating must be retested annually.

Coatings can, and often are, tested to standards that only represent a portion of the whole standard. In the case of UL94, this is helpful when flammability is the main concern. Some specialty coatings may not be tested to the entire IPC-CC-830B or UL746E standards because they may fail parts of the test. These failures may be due to the nature of the product and the coating’s necessary applications, and are not always a reflection of the quality of the product. For example, some coatings intended to coat LEDs leave out the UV indicator to prevent color shift, but this automatically would cause disqualification under IPC-CC-830B. In other words, it is impossible by definition to pass IPC-CC-830B and have optical clarity in the UV part of the spectrum.

Regulatory Considerations

Safety and environmental considerations should always play a part in chemical selection and process design, but different regulatory bodies make this an even more challenging feat, as requirements must be interpreted and matched with product specifications.

OSHA (Occupational Safety and Health Administration) - In the US, the OSHA has overriding authority over worker safety concerns. Many coatings are very flammable, and many emit fumes that have a high level of toxicity. Close attention needs to be paid to ventilation (explosion-proof when dealing with flammable fumes) and the appropriate PPE (personal protection equipment) to keep operator exposure down below the appropriate safety threshold. Flammability may be difficult to avoid without exploring more specific water-based coating materials. Newer coatings have been introduced that do not include HAPs (hazardous air pollutants – a government classification of particularly toxic chemicals) like toluene, xylene or methyl ethyl ketone (MEK). The Global Harmonized System (GHS – with those red diamond symbols) needs to be followed for labeling, which is generally taken care of by the manufacturer. Make sure safety data sheets (SDS) are readily available to operators, as they should be for any hazardous chemical in a facility.

EPA (United States Environmental Protection Agency) – In the US, the EPA requirements must be followed at the national and regional level. The EPA, following the Montreal Protocol treaty, enforced restrictions on ozone-depleting chemicals. Since most of the restricted chemicals are unavailable and have not been used in conformal coating formulation for years, ozone depletion isn’t the current concern. If there are regional agencies (see next paragraph) that have stricter requirements than the EPA, those generally will need to be followed.

CARB (California Air Review Board) and other regional regulations – Local agencies continue to play a larger-and-larger role in environmental restrictions. CARB was one of the early regulatory bodies, laying down VOC (volatile organic compounds – smog-producing chemicals) restrictions by product category. Other regional agencies followed their lead. Global warming potential (GWP) is the latest environmental topic of discussion.

This concludes our guide on conformal coating. We hope that it answered your questions and provided proper guidance in selecting the best products and methods for your needs. Like any challenge, selecting the best coating and coating process can be broken apart, analyzed, and solved.

Now we want to turn it over to you...

What did you think of this guide? Maybe there is something we missed. Let us know by leaving a comment with your feedback. Techspray has experts available that will guide you all the way through the selection and qualification process.